Effective product transfers ensure quality, efficiency, and safety in any production line. Whether a product needs to be transferred from… Read more »

Category: Engineered Solutions

Save Space and Simplify Operations with Elevation Conveyors

In modern manufacturing facilities, space is premium, and every piece of equipment must work in sync with other machinery and… Read more »

Dorner Conveyors Help to Solve Pharmaceutical Industry Challenges

The pharmaceutical industry constantly evolves to meet new demands and patient needs while striving to operate as safely and efficiently… Read more »

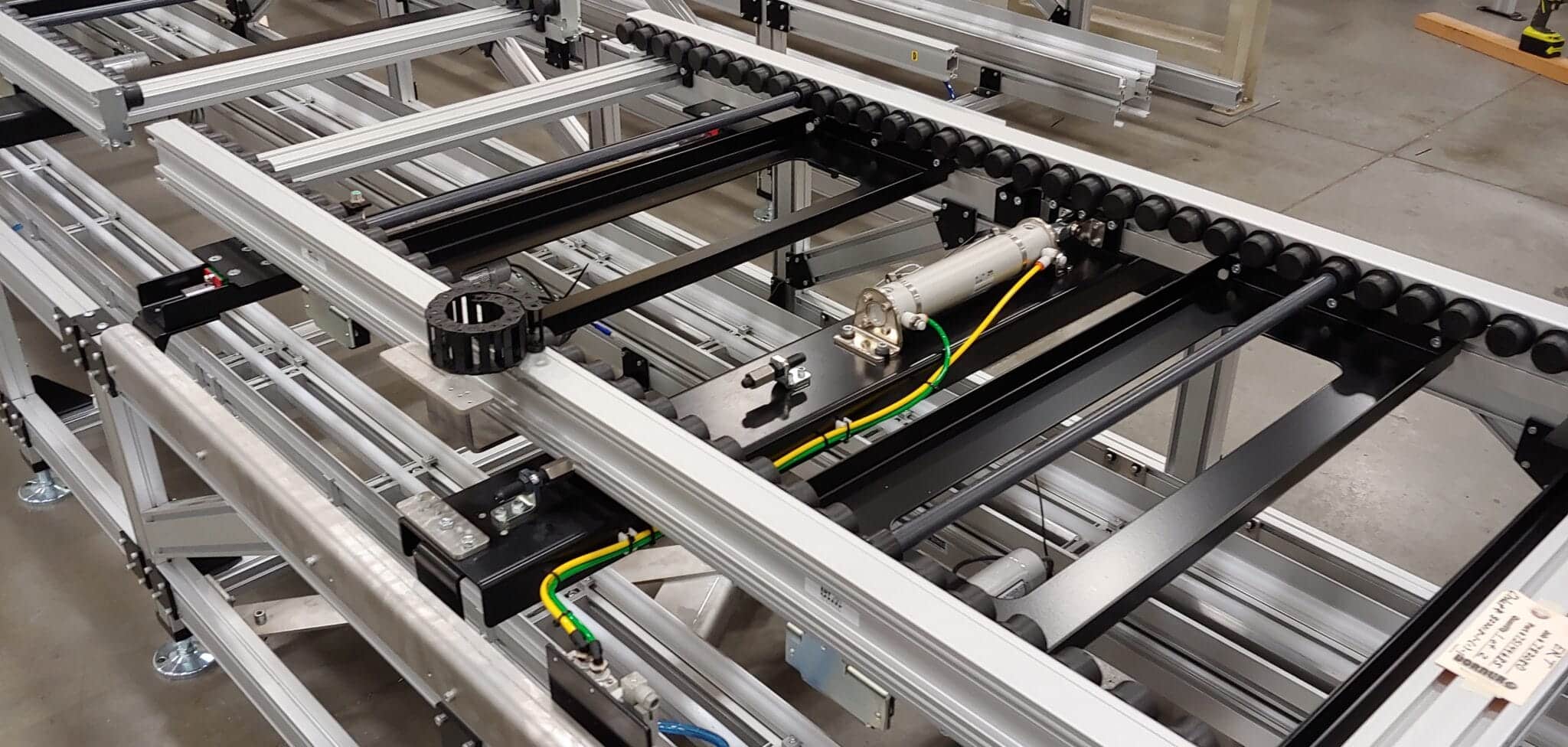

New Conveyor Projects in the Shop

The new year has brought many new projects into the shop at Dorner’s Hartland facility, and our Engineered to Order… Read more »

Supply Chain Integration: Streamline Your Processes With Dorner Conveyor Systems

Supply chain integration is an ongoing process of connecting suppliers, manufacturers, and distributors into the same system with unified goals.… Read more »

4 Factors to Consider When Choosing a New Conveyor

Many factors can go into choosing a conveyance system that meets both industry requirements and your company’s unique needs. That’s… Read more »

Optimize Space with Conveyor Elevations and Line Egress Solutions

Why Systems Need to Be Flexible Modern manufacturing requires facilities to maximize efficiency and ensure product quality. However, space… Read more »

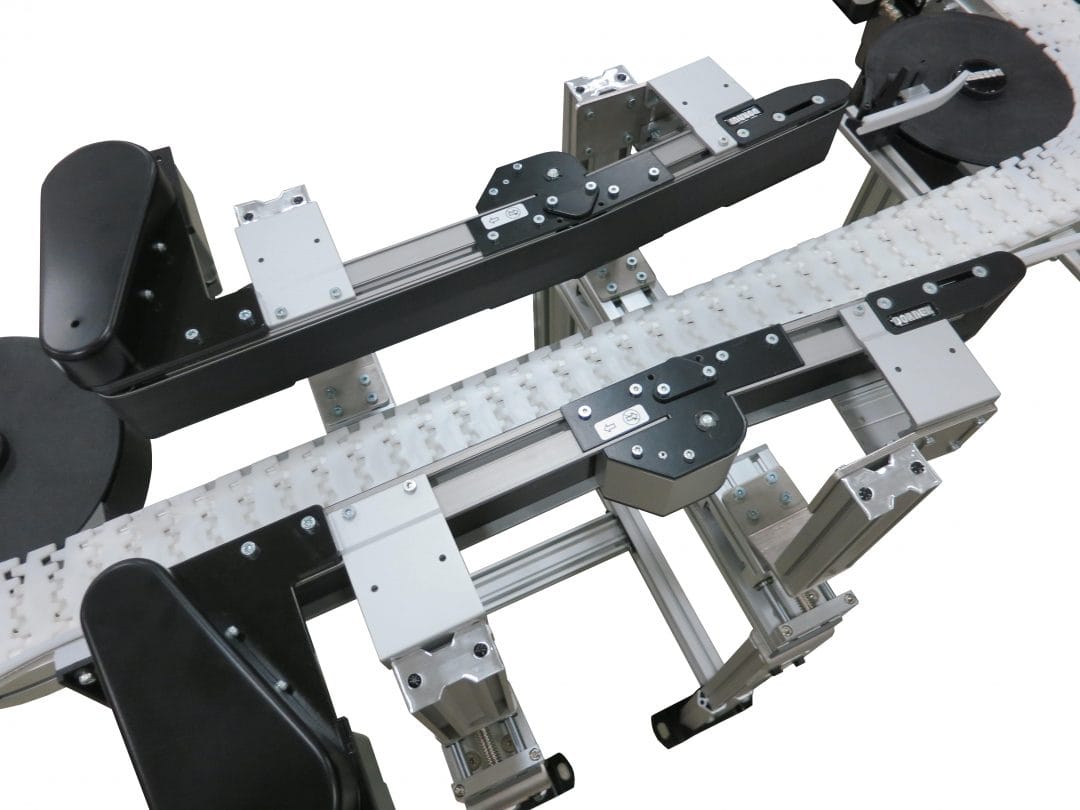

Dorner Engineered Solution – Recirculating Conveyors

Manufacturing lines require mechanical solutions to facilitate the consistent flow products to maximize throughput, and recirculating conveyors are a… Read more »

Easy 90 Degree Transfers

Transferring products is a necessity in many conveyor system layouts. Whether you’re transporting a product onto another conveyor line… Read more »

Save Time and Money with Dorner’s Engineered Solutions

Do you have an application that calls for an extra-long conveyor, but an existing obstruction is hindering the installation of… Read more »

Elevator Provides Additional Product Storage for Accumulation System

See the system in action at the end of the post! When downstream equipment is non-operational, an accumulation system can… Read more »

Can Dorner Design A Solution For Your Application?

Dorner’s Engineered Solutions Group (ESG) can create a custom conveyor or conveyor system for almost any customer need. Dorner has… Read more »

Retractable Tail Provides Simple Walk-Through Access

Space can be limited on the factory floor and equipment isn’t always easy to access. Conveyors and other machinery… Read more »

6 Ways to Use a Bottomless Conveyor

Bottomless conveyors, also called side-gripping conveyors, provide a simple solution for accessing the underside of a product for a… Read more »

Merging and Laning System for Sauce Packaging

Often during the packaging process, product needs to be either merged or separated into separate lanes as it moves… Read more »

Large Custom Appliance Conveyor System for Assembly Automation

Recently, Dorner provided an extensive custom conveyor solution for a customer looking to assemble large appliances. The system, designed by… Read more »

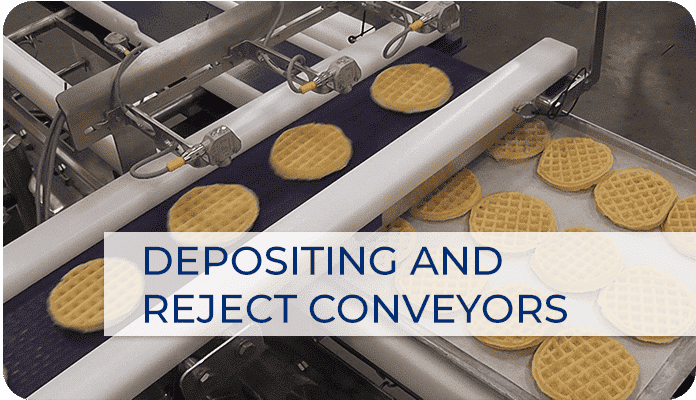

Dorner’s Custom Depositing and Reject Conveyor Systems

Rejecting Conveyors Why is rejecting necessary? Rejecting is a necessary step in any production line to help increase the… Read more »

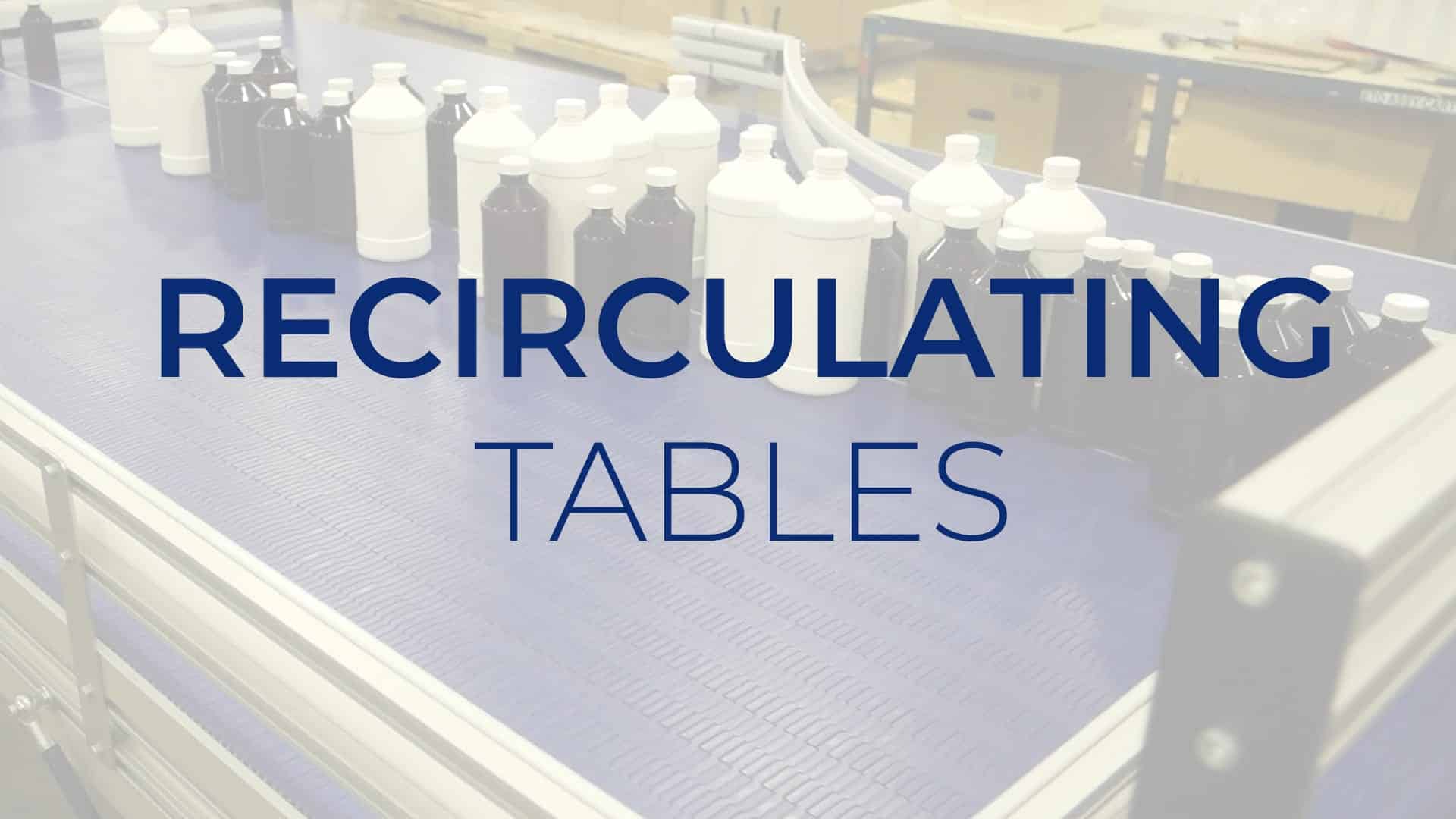

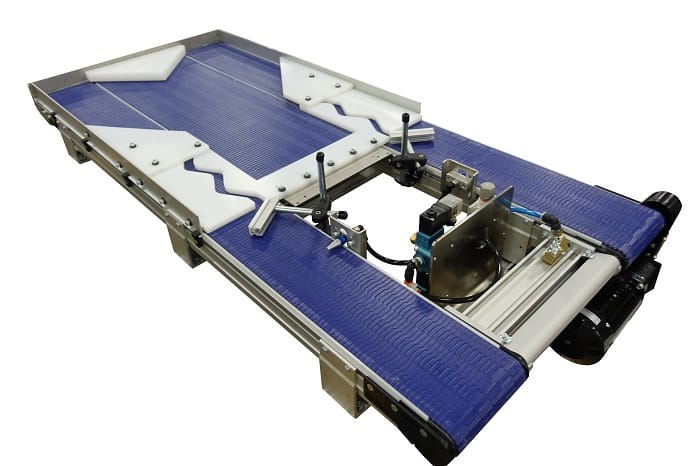

5 Important Facts About Dorner’s Recirculating Tables

See our recirculating tables in action at the end of the post! 1. They enable product lines to keep pace… Read more »

Create Safe and Fast Walk-Through with Lift Gates

Lift gate conveyors are a popular solution for creating safe and fast walk-through access to maximize usable space. Take… Read more »

How do Diverting and Sorting Conveyors Work? Take a Look.

Conveyor diverters and sorting conveyors work by handling product based on such characteristics as weight and shape along with line… Read more »

Add Simple Automation with Retractable Conveyors

A retractable conveyor, or retracting tail, is a conveyor frame with the ability to retract or extend, typically on… Read more »

Dorner Merge Conveyors

Dorner offers a variety of solutions for merging products in a processing line. We can merge 2, 3, 4 or… Read more »

Sanitary Helix Now with Added Features

As we’ve highlighted in the past, Dorner has created Sanitary Helix designs to integrate with Hoosier Feeder’s Food Grade Centrifugal… Read more »

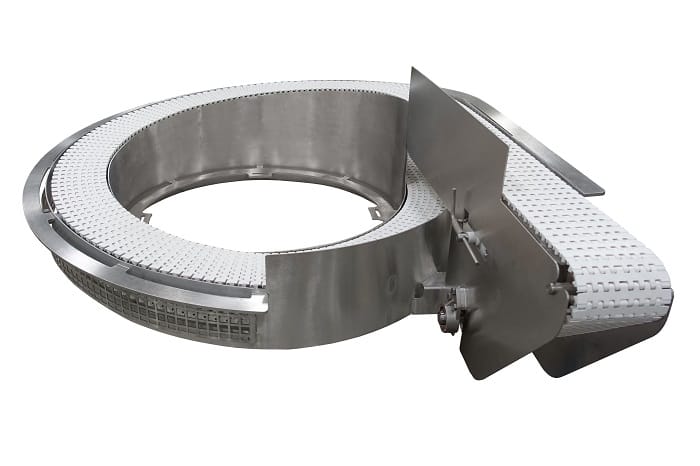

Custom Accumulation Systems

When you need to ensure a steady supply of product to a machine or to hold a supply of product… Read more »