The Role of Hygienic Conveyors in Allergen Control: How Quick-Clean Designs Prevent Cross-Contamination

Allergen control is one of the most critical components of food safety in today’s manufacturing environment. With strict regulations like

Allergen control is one of the most critical components of food safety in today’s manufacturing environment. With strict regulations like

In manufacturing, the cost per square foot of a facility is a metric that is constantly scrutinized. As throughput targets

Discover how configurable, modular conveyor designs reduce installation time, lower costs, and provide unmatched flexibility for automation integrators and manufacturing

Manual material handling remains one of the leading causes of workplace injuries across manufacturing and logistics facilities worldwide. When workers

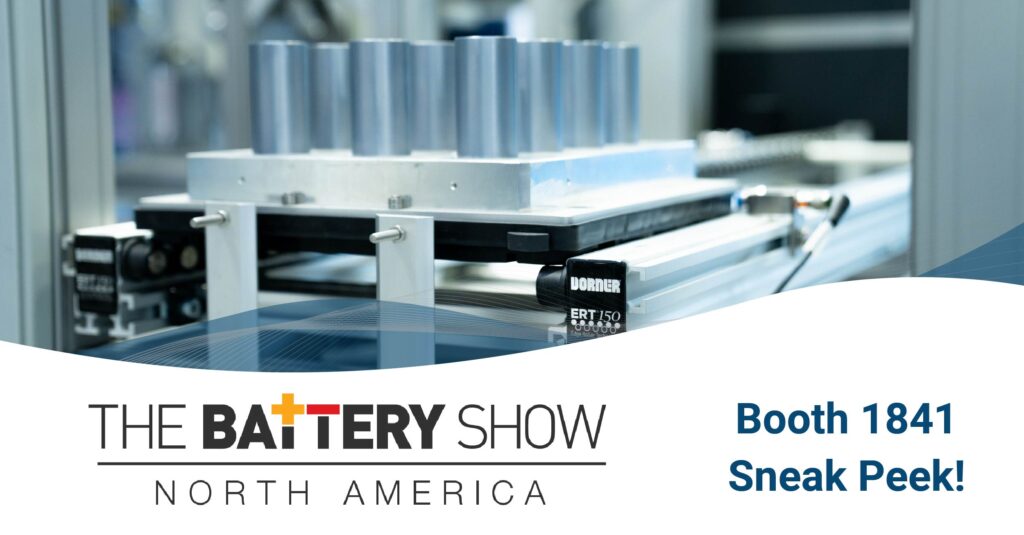

Columbus McKinnon Conveyance Solutions Group Showcases Advanced Battery Manufacturing Technologies at The Battery Show 2025 in Booth 1841 Industry leaders

In modern manufacturing, maximizing production efficiency while minimizing downtime is crucial for maintaining a competitive advantage and meeting customer demand.

Industry leaders Dorner, Garvey, and montratec, part of the Columbus McKinnon family of brands, are highlighting their latest conveyance technologies

Product damage during conveyor transfers is a significant concern for manufacturers, as it directly impacts bottom-line profitability through waste, rework,

Maintaining product safety and preventing contamination is paramount to protecting both consumer health and business reputation. With foodborne illnesses affecting

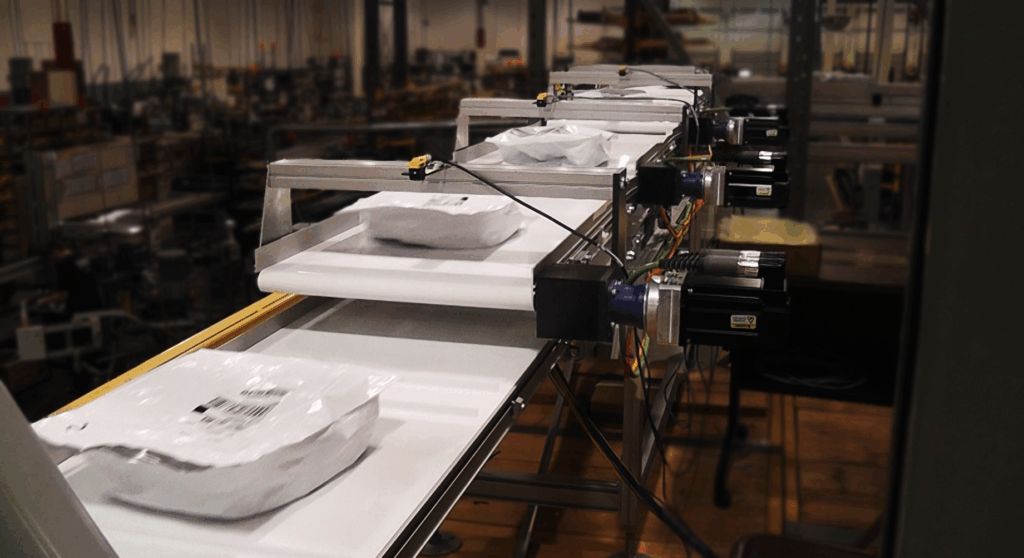

Distribution centers and e-commerce operations face unprecedented challenges in today’s fast-paced market. High-volume order processing, diverse product sizes, and rapid

In today’s fast-paced production environments, maximizing space and efficiency is more crucial than ever. Dorner’s newest addition, the FlexMove Retractable

The landscape of modern warehousing has undergone a remarkable transformation since the first conveyor belt systems revolutionized material handling operations

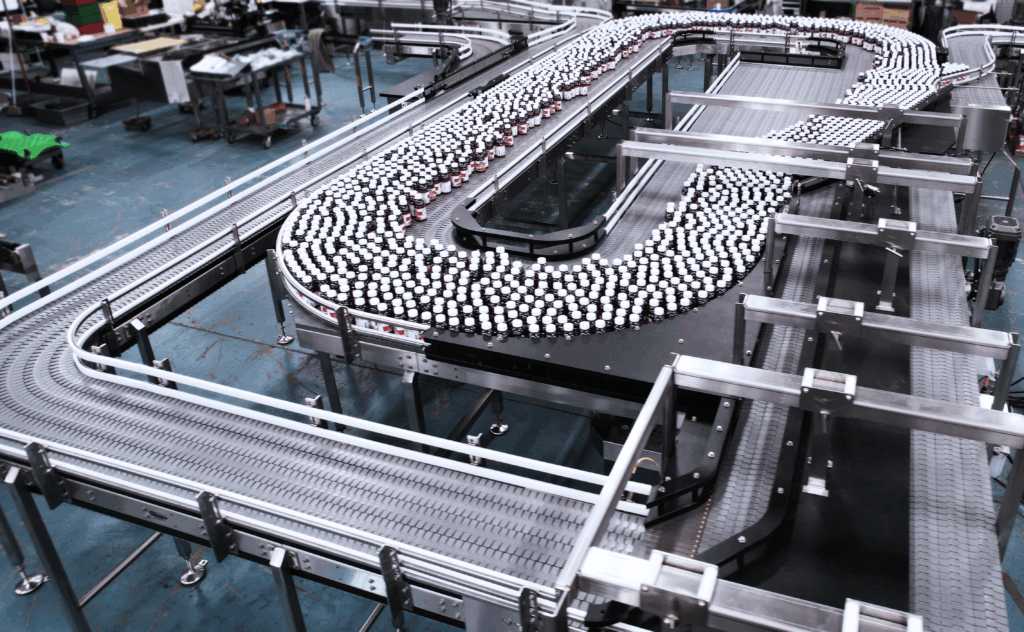

In today’s fast-paced manufacturing and packaging environments, maintaining efficient product flow is critical to maximizing throughput and minimizing downtime. Accumulation

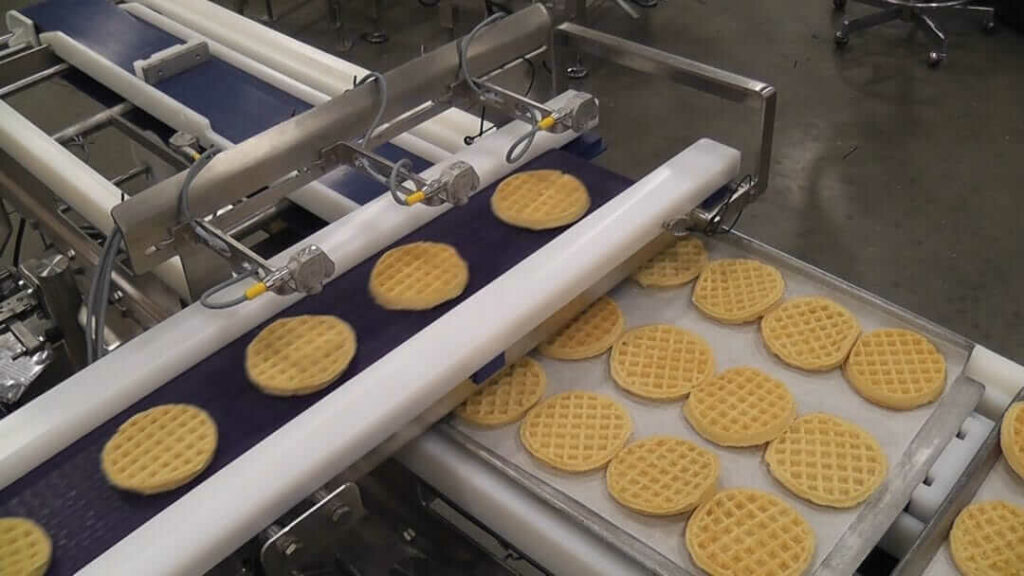

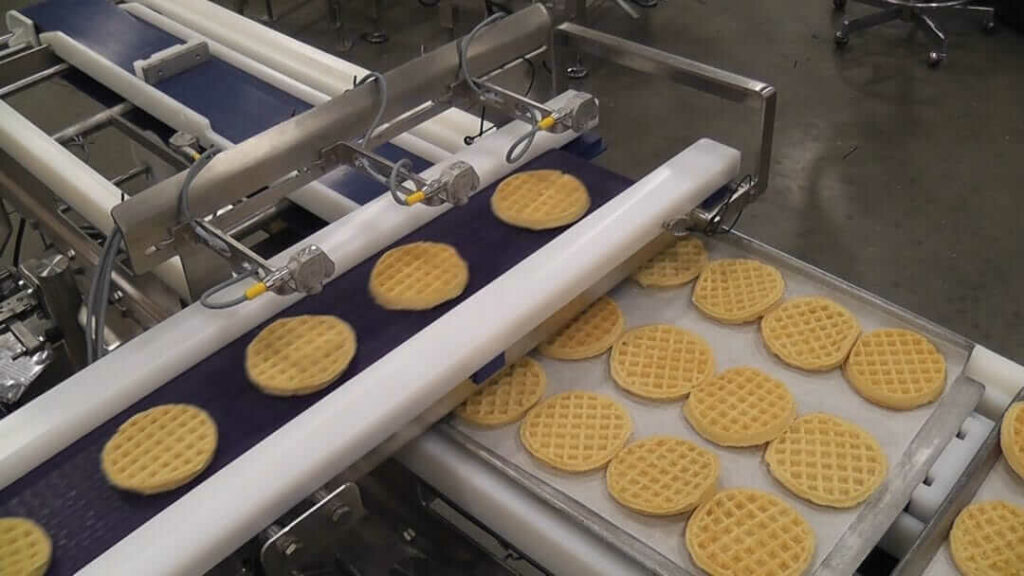

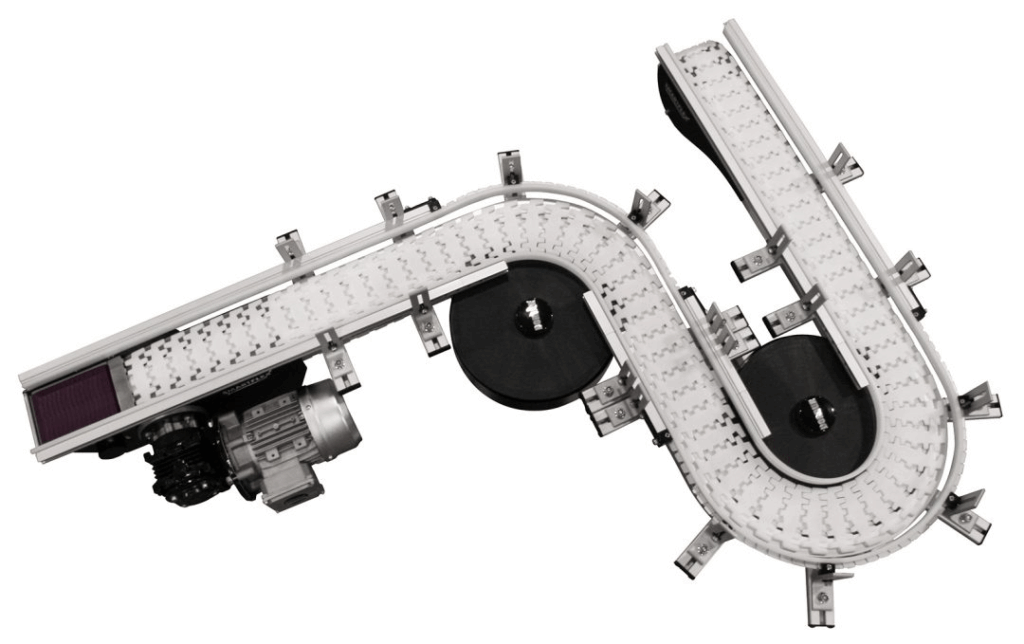

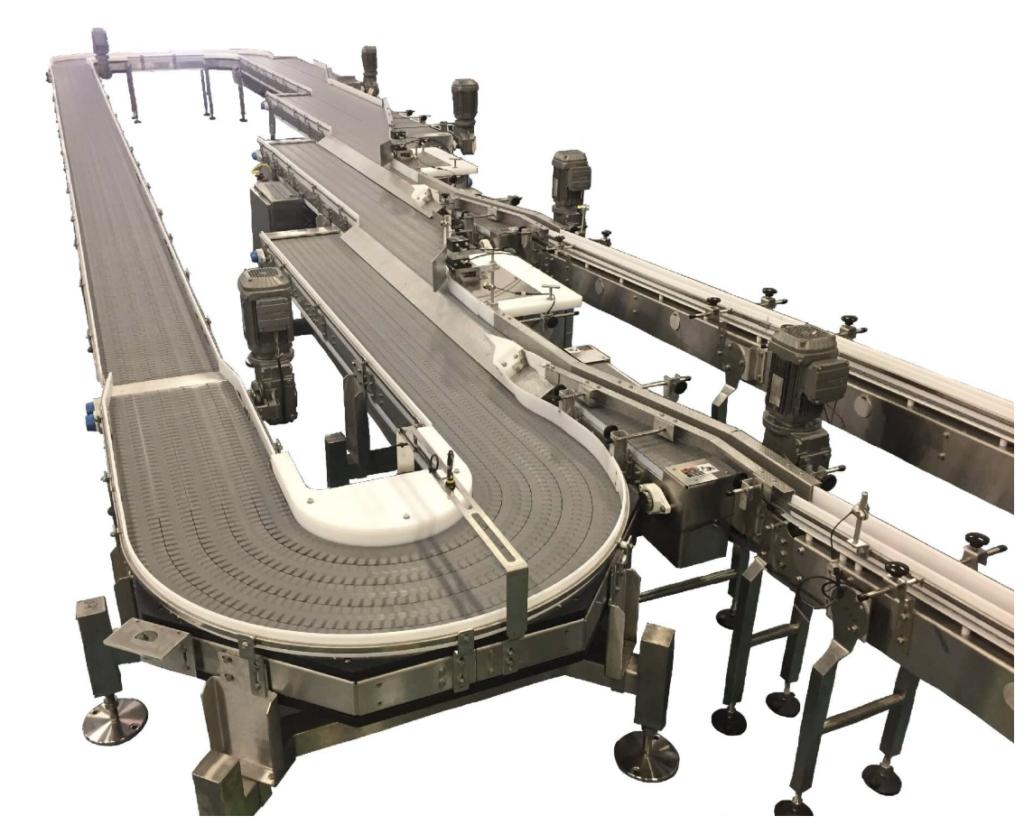

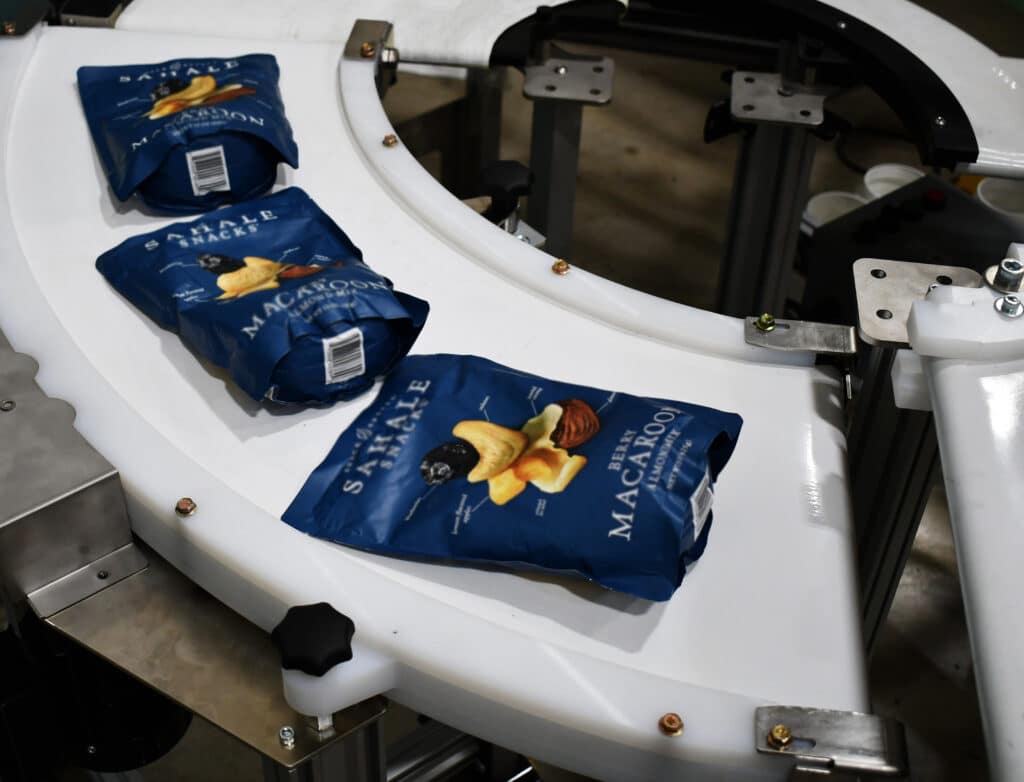

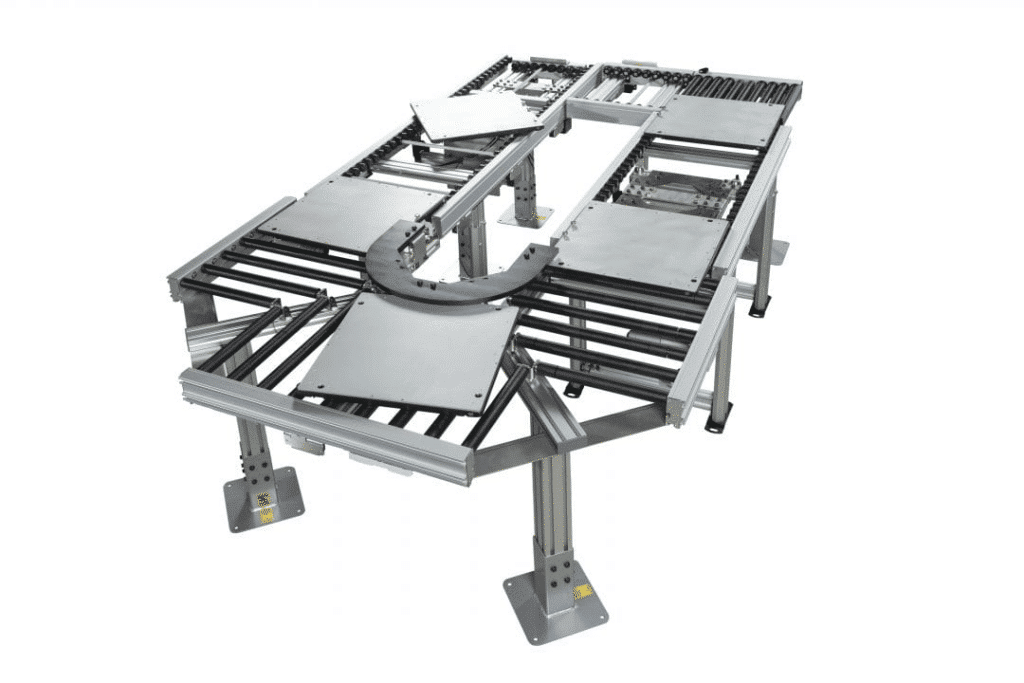

The C3 Compact Curve Conveyor is a game-changing solution designed to optimize packaging processes across the packaged food industry. By

The C3 Compact Curve Conveyor can be utilized in a bakery production facility needing to handle unpackaged and packaged bakery

Reinforces CMCO’s growing leadership position in the fast-growing electrification and battery production vertical end market Reports fourth consecutive quarter of

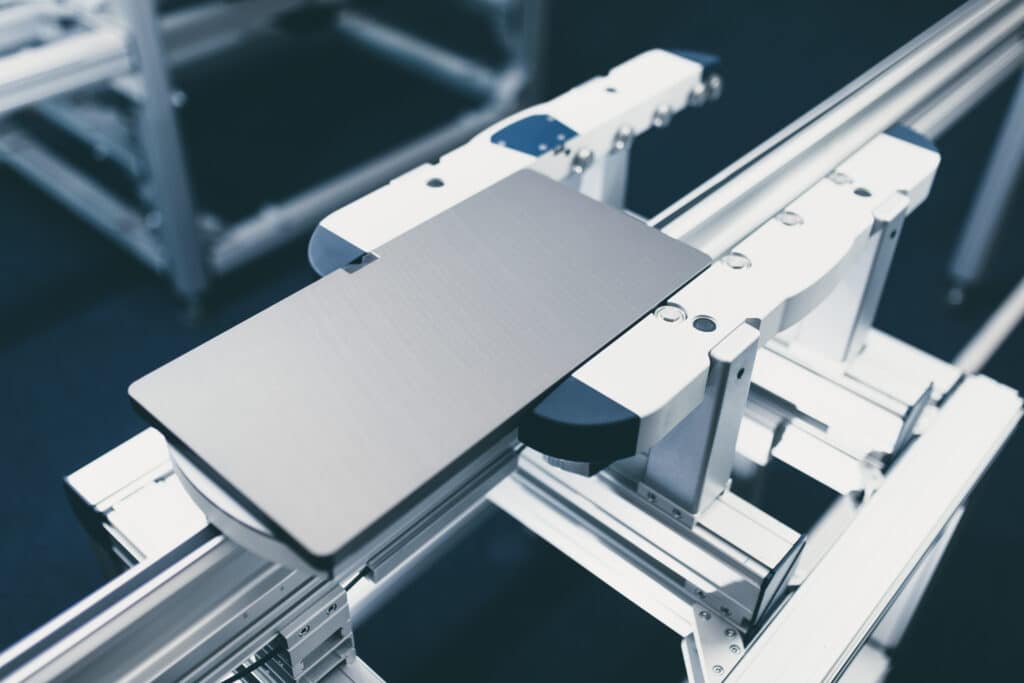

Curved conveyor systems are crucial in many production lines—particularly those dealing with delicate or complex materials that must navigate turns

Industrial conveyor systems have become an indispensable part of manufacturing automation, serving as the backbone for many modern production lines.

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

Conveyor belts have long been the heart of modern manufacturing, logistics, and distribution. From speeding up product handling to improving

Small conveyor belts are revolutionizing the way companies handle product movement in industrial automation, medical device manufacturing, e-commerce, and more.

It is that time of year again for Pack Expo International! The Dorner team has been working hard for months

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

In the world of automated guided vehicles (AGV) and montrac® shuttle conveyors, there are several misconceptions to be addressed. Let’s

Behind the Conveyor – Team Spotlight Dorner has become a global brand in conveyor automation – and that’s all thanks

HARTLAND, Wis., (August XX, 2024) — Mark Schmid has been appointed Regional Sales Manager, covering the upper Midwest portions of

Battery Show North America is coming up fast, and the Dorner team is excited to showcase battery and electronics conveyor

The medical device manufacturing industry faces a unique set of challenges. Precision, cleanliness, and efficiency are not just goals —

HARTLAND, Wis., (August 30, 2024) — Tim Patt has been selected as Regional Sales Director for Dorner. In this position,

With new medical discoveries being made seemingly every day, the medical device industry must quickly evolve to create new and

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy

We may place these for analysis of our visitor data, to improve our website, show personalized content and to give you a great website experience. For more information about the cookies we use open the settings. Privacy Policy.